Crazy for Innovation

Crazy for Innovation

Crazy for Innovation

Crazy for Innovation

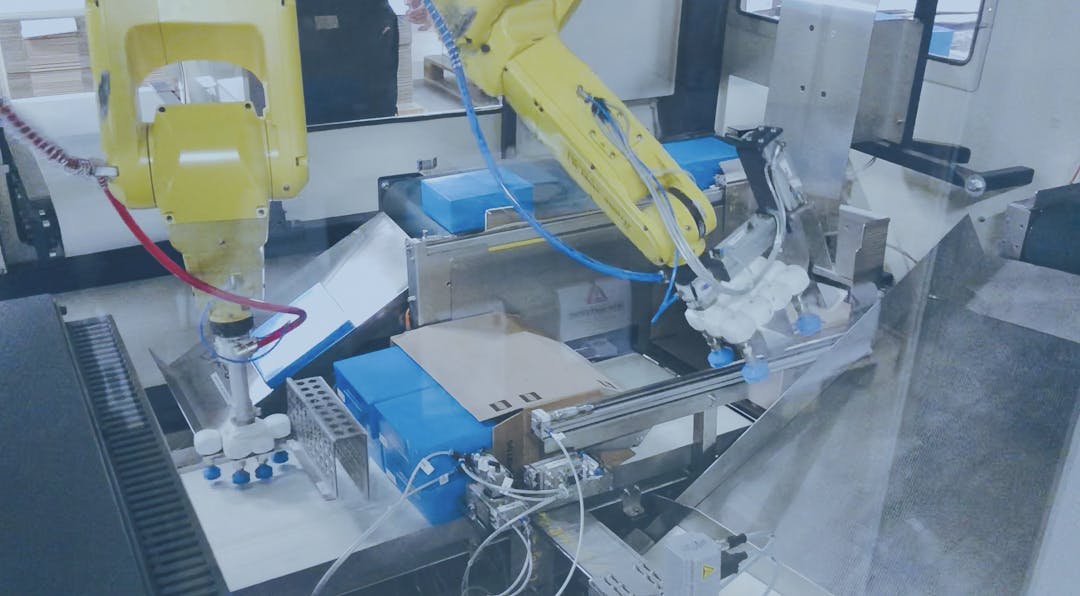

KRAPCO specializes in long-term research, development, and implementation of the most advanced technologies into processing factories. Core portfolio consists of universal Pick-and-Place Robotic machines, Sorting machines, and fully automated Processing factories. Our priority is to provide efficient innovative solutions by continuously keeping pace with technological advancements.

Innovative solutions for fast and efficient packaging into cartons. We offer an unmatched method of handling individual or pre-packaged items.

Precise and reliable solutions for material sorting, not only for the food industry. Extensive range of machines has been developed after 20 years of R&D and collaboration with leaders.

Efficient and specialized solutions for cracking shell fruits, ensuring material suitable for further processing in a food environment.

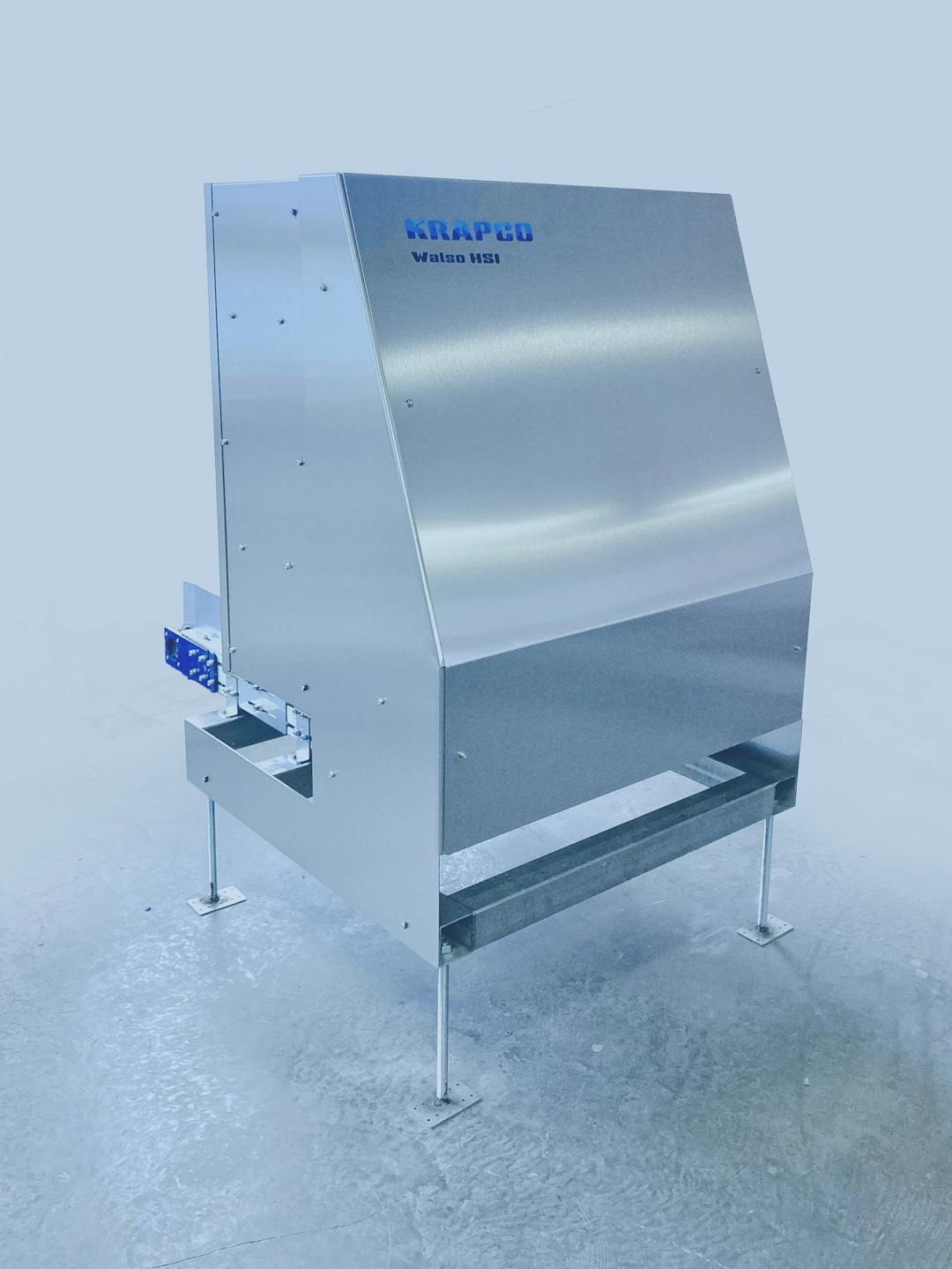

Stainless steel storage solutions ensuring hygiene, efficiency and seamless material transfer, while being fully customizable.

Ideal solutions for the necessary accessories to operate our equipment, ensuring streamlined and improved processing efficiency.

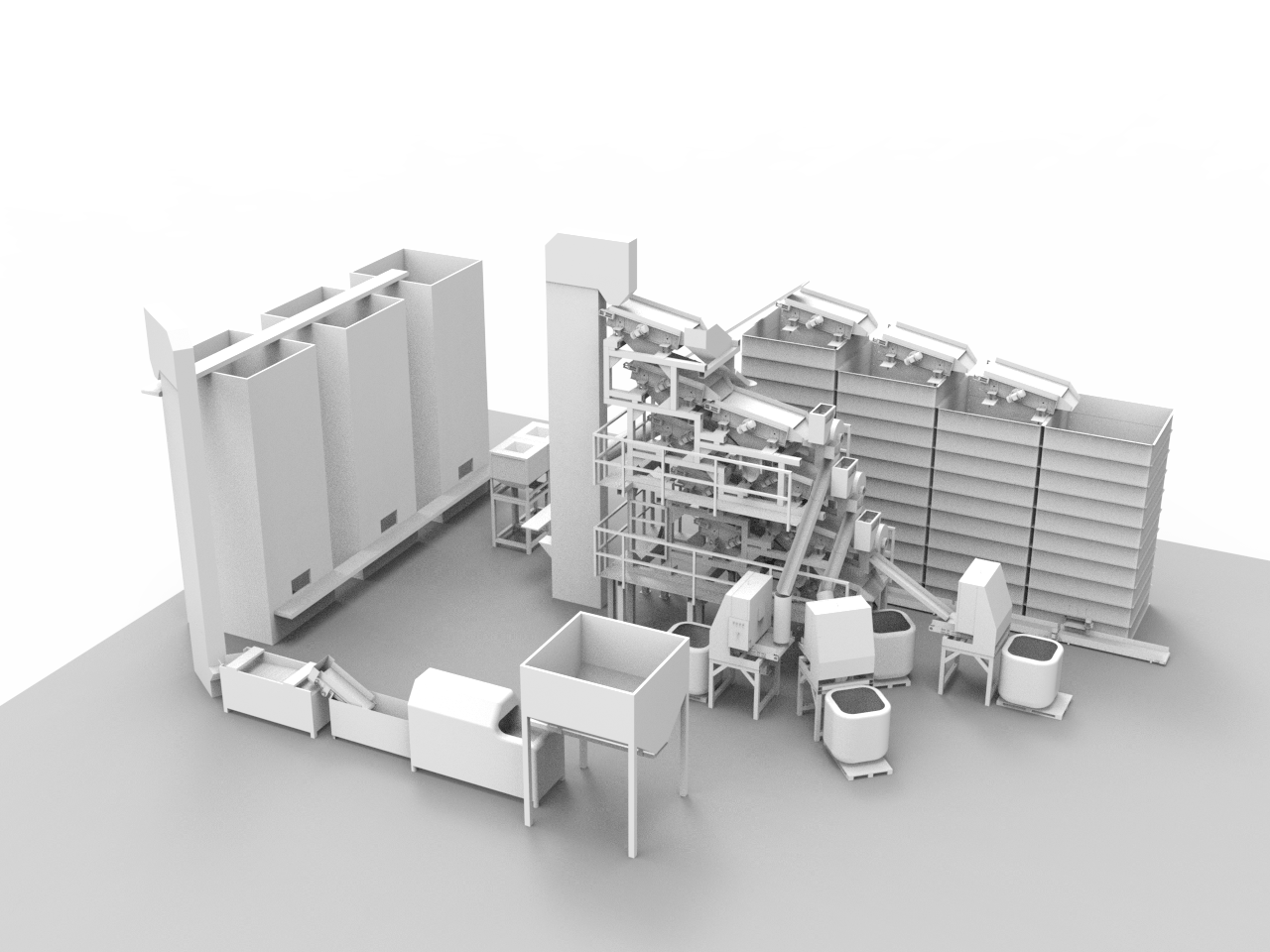

KRAPCO specializes in supplying fully automated complete Processing factories for shelled fruits, offering a comprehensive range of technologies to support every stage of the production cycle, from nut washing and cracking, calibrating and sorting, right through to the final packaging.

Submit your specific requirements

Send your material for testing

Recieve offer which meets your requirements

Negotiation of the next steps of cooperation

Sign a contract

Implementing technology to your factory

Training the operators

After-sale services

Our service team is ready to help you with any issue.

We constantly keep up with technological advancements and inform our clients about mechanical and software innovations.

In the case of time-consuming repairs, we offer a one-to-one machine exchange, ensuring uninterrupted operation for you.